More Vinyl talk, while I prepare records to blog next.

The record cleaning mix muddle

Tired of paying £20 for a litre for record cleaning fluid for your vacuum machine, and waiting weeks for the postman to call each time you run out? I decided to try-out as a celebrity vinyl mix-master. A quick internet search on how to make record cleaner threw up loads of second and third hand information: assorted home-made recipes and much poor quality advice – superstition, old wives tales, urban myth, contradictory claims, and in some cases, stupidity, however well intentioned. Typical of what you find on hi fi forums really. Some quotes:

Strategic misdirection

- I caution against home brew concoctions. Store bought ingredients simply can’t match the purity of commercial formulations.

- I took the LP to the sink, gave it a good dousing of Windex and wiped ‘er down with a fresh J-Cloth…. The result was astounding. The record sounded mint!

- 400ml water, 2 drops of household washing up liquid and a cap of malt vinegar

- Squirt lighter fluid on a clean, soft cloth and gently wipe the record surface. The lighter fluid will evaporate, so the record doesn’t need to be rinsed.

Water source

- I’ve used the melted ice from my freezer (filtered), as my physics lecturer and

audiophile friend says this is as good as any other. - We’re talking about ‘safe for human consumption’ tap water here, isn’t this preoccupation with absolutely pure water a little anally retentive?

Alcohol dilution

- I use roughly 1 part Isopropyl to two parts purified water …..

- 90% Isopropyl Alcohol, 5% – Anti-Microbial soap 5% – de-ionized water

- Those of you that use Isopropyl you must be careful: Isoproply will harden vinyl.

- It does NOT harden vinyl – there is absolutely no chemical reaction between PVC and/or PVA

Wetting agent (a recipe for confusion)

- A few drops of photographic wetting agent. … just a drop of washing up liquid as a wetting agent ….. 10 drops Photo-Flo + 10 drops “Direct” tile cleaner ….. a teaspoon of car washer fluid ….. 7-8 drops dishwashing detergent without additives ….. 1 drop Triton X-114 or Monolan 2000 ….. 10 drops of Kodak Photo-Flo and 10 drops of Lysol Antibacterial All-Purpose Cleaner….Dawn Dishwashing Fluid,…. few drops of dish washing soap without lubricants. …..3-4 drops per gallon Kodak Photoflo …..a few drops of Ilfotrol photographic wetting agent.

BS-BUSTING LJC FORMULA, TRIED AND TESTED, SAVES TIME, NO WORRIES

Scientific method

So here we boldly go with the LJC record cleaning formula.

I took the best of recipes that makes sense to me, and tested experimental quantities of secret ingredient wetting agent using record A and B sides as a control for different strengths on the same record, first washed, repeat washed, all the while watching the wetting-in behaviour closely. All records play-tested after vacuuming.

Purest ingredients

I bought the highest laboratory-grade pure ingredients I could find, 99.9% purity, from reputable on-line suppliers. Nothing was sourced from local stores destined for the household shelf, nor for other purposes like top-up water for batteries. I wanted to save money but not take risks for a few pence.

Having washed records with alcohol and water based commercial cleaner for four years I don’t have the slightest concern and do not accept the unsubstantiated Wikipedia claim isopropyl alcohol “hardens” vinyl, which claim lacks any citation or proof, but is repeated by sellers of non-IPA formulas. Well they would, wouldn’t they.Though known to be unsuitable for shellac 78’s, well diluted Isopropyl alcohol has been used for decades for professional cleaning of vinyl without any evidence of harm. Ethanol-based formulas like Knosti may suit those of a more nervous disposition.

The Final LJC Formula

Surfactants – the all-important “secret” ingredient

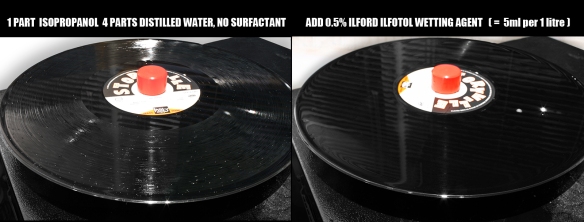

Starting with pure IPA/Distilled water at the most commonly recommended dilution in commercial preparations – 4 parts water 1 part IPA – the surfactant quickly proved the critical variable. A neat mix of alcohol and water does not “wet” and won’t penetrate the grooves. Instead, within seconds, it draws back from the vinyl, forms rivulets and pools, drawn to itself.

The solution is an ingredient borrowed from the photographic industry where the same need was encountered for washing photographic films and papers. “Wetting agent” reduces the surface tension of water, and was developed to ensure even coverage of photographic film, drying evenly without water marks or residue, and imparting antistatic qualities. Washing up liquid and car screenwash are not anything I would risk on a £100 record..

However, the quantity of wetting agent to add mystified many people, me included, and commercial manufacturers won’t say. “A few drops” is the most common DIY advice, though people forget to say what quantity they are adding it to. I tried everything experimentally from a five to fifteen drops per litre and it was totally ineffective. Water would not wet. Consulting the manufacturers data sheet, Ilford recommend a start point dilution of 1:200 – 5ml per litre, equivalent to 150 drops. Ilford have been making wetting agent for decades, photographic professionals entrusting negatives from film shoots costing hundreds of thousands of pounds to this dilution of wetting agent. Might they know what they are doing?

I upscaled to the recommended film-washing dilution of 5ml per litre, and bingo, suddenly everything fell into place. This tiny correct quantity completely changed how the fluid behaved. No vinyl resistance, cleaning fluid lay flat on the surface like glass, no drawing back from the vinyl, it truly wets, vacuums off perfect, no residue or marks, record plays perfectly.

The advice I read in a hi fi forum “you will know you have added too much wetting agent, as it bubbles up” wrote one forum poster, is the complete opposite of what happens. It “bubbles up” when you have not enough wetting agent. Some research on “surfactants” suggested their rate of dilution accords to different effects. At very low levels they act as an emulsifier, at a higher level they act to reduce surface tension (wetting agent) and at higher still, they become a detergent.

Whilst some recipes call for “a few drops” of something, we don’t know its degree of concentration. A few drops of X might well be the same as 100 drops of Y if Y is prepared for consumer use already in a more dilute form. I tested half Ilfoltols recommended 5ml per litre and it still wetted well, though a little more hesitantly. If you were concerned, around 3ml per litre would still work well enough.”A few drops” is a complete waste of time. Incidentally, 5ml is considered in plain English as “a teaspoon full”.

One tool which is essential in all record cleaning is a 5ml oral syringe.Not only will it control the exact dosage of preparations, it ensures you administer the correct amount of cleaning fluid to the record surface – 2.5ml per side is exactly enough to get good coverage of the vinyl surface, controlling the delivery to keep it away from the label, and sufficient not to start evaporating during the few minutes of a cleaning session. Cheap and after a few months use, replace.

Five litres are good for a year or two’s supply, one-third of the retail cost of the cheapest proprietary commercial record cleaning product. Convenience and simplicity in a bottle

The most important discovery

Little did I anticipate in 1990 that I would need to label polypropylene bottles of record cleaning fluid. I have finally found a use for the packet of 3.5″ floppy disc labels I have been keeping since 1990, “just in case”, at a stroke proving wrong the fragrant Mrs LJC, who throws away anything she can not see an immediate use for.

Everyone has hindsight. But foresight? It’s a gift, you know.

LJC is this DIY solution superior to your Knotsi/Moth commercial fluid you wrote about in August 2012? Cheers

LikeLike

My recipe is the same formulation as Moth’s own cleaning solution, at a third of the cost. As regards Knosti Discostat – that is ethanol-based rather than Isopropyl, priced about the same as Moth.

There is an ingredient in the Knosti – I have no idea what – that gives it rather better anti-static properties than the Moth formulation. If cost is not a consideration, I’d say Knosti Discostat has a performance edge.

In day to day use, I think the Moth/LJC formulation does an acceptable job, I can afford to use it generously, and I never run out.

LikeLike

Excellent thanks.

LikeLike

There’s a question at the end here, so stick with it:

I’ve been thinking about stepping up my record cleaning game – I don’t have nor will I have a record cleaning machine anytime soon, and I’m sure that plenty of folks will tell me that any improvements are useless without the aid of vacuum cleaning, but oh well.

The record that prompted me to think on this was an early mono pressing of Max Roach’s “It’s Time” ( Impulse, my copy says “Am- Par” on the bottom of the label). It’s a full house, between Roach’s drumming and the use of a choir. I bought it yesterday at a record show…seemed grody but didn’t have any vicious looking marks.

I played it a little on headphones ( baby was asleep) after just brushing it off and I was not enthused about how clumped together everyone sounded. When the voices got out of the way, Junior Cook didn’t really come forward in the mix as he took his solo. There was definitely some noise competing with the music although in a way that is a little subtle, you turn up and turn up until it hurts your ears to hear it all.

Cleaned the record and there were definite improvements. Kind of a similar experience to the description of the “futile” cleaning efforts mentioned in the article that someone linked in a previous comment. In that article, the author mentions using cotton pads to get the initial gunk off of a record and to be able to witness just how clean the record is getting (via the color of the cloths). I need to do this because using a year old Audio-Technica brush is obviously probably spreading the dirt from one record to the next. Plus you want to know that you are in fact removing filth and how filthy the record truly is – my record collecting motto is “knowledge is power.”

I am expecting marginal improvements if I switch to applying cleaner with cotton pads and then absorbing the liquid with a clean record brush (or dry cotton pads, if that’s safe) while at no time using a vacuum. However I expect the results to be sufficent and maybe surprisingly effective for my available resources.

My question, and it may be a useless one: besides the obvious cracklings and perhaps pops, what are the things you should notice when listening back to a well cleaned record? More importantly, what have you found in your listening experience that CANNOT be conquered by cleaning? I’m expecting the typical groove wear distortion that can be typical with old mono records, but I’d love to hear if anyone has found that they have ever found any kinds of distortion lessened due to cleaning. Any thoughts on this redirected topic? It would be good to understand what my cleaning efforts are actually helping to accomplish.

LikeLike

A fifty year old record which has never been properly cleaned (solvent+vacuum) is immediately obvious on the turntable. The stylus gunks-up smudging the sound. Single rev clicks and pops (crap in groove – not scratches) dominate the opening few minutes. The grooves contain mould-release, condensed cigarette residue, finger-print grease, compressed dust, even deposits of cooking fats. Blur and smear as the stylus slooshes through.

After proper cleaning, 80% of that stuff should go away. What wont go away are physical scratches that cut deep into the groove, groove wear, and crappy pressing. Nothing can improve those. The vacuum is essential to remove the crap residue, otherwise you are just moving it around.

My Moth Pro Vacuum RCM cost £400, and the fluid I have got down through home brew to a few pence a record. I have only one question. Why would you not want to hear every record “as nature intended” .? I couldn’t manage without it.

LikeLike

Oh, I’m sure that having a vacuum machine is worth it. Someday perhaps I’ll have one.

The variety of dirt you can encounter is incredible. I have a copy of Coltrane’s Black Pearls I just got in the mail a few days ago. It was so grody even after brush and solution that it still left gunk on the stylus. I just cleaned it again using cotton pads, cleaning fluid, then pads and distilled water, then dry pad. What came off the record was clear, nothing disgusting, but damn if it didn’t have a clear as a bell sound when I was done. I think the distilled water is key – I was brushing off the alcohol solution with a dry part of the brush but otherwise it was evaporating, probably leaving a film that held off that last 10% or so of the clarity on the top end. We will have to see if it makes a difference on other LPs.

LikeLike

Can anyone confirm or disprove the statement I’ve heard that playing a dirty LP once makes the dirt in the grooves become part of the record itself and therefore impervious to cleaning?

LikeLike

I believe I was first exposed to this concept in this article, “The Most Comprehensive Record Cleaning Article Ever!” by Michael Wayne:

http://www.analogplanet.com/content/most-comprehensive-record-cleaning-article-ever-0

This is generally referred to as ‘welding’ with the idea being that the pressure and friction at the stylus contact point briefly renders vinyl viscous enough that debris becomes physically embedded in the surface. Much like LPs rendered brittle by alcohol cleaning, no one seems able to provide any real evidence of the occurrence of this phenomenon.

After cleaning, I examine the surface of all of my LPs for any foreign matter with a very bright white LED flashlight. In my experience, anything that is not PVC will be readily visibile under this lighting. Most LPs after cleaning show up almost jet black with the exception of the few hairs and dust which have already managed to make their way back to onto the surface of the LP in the interval between being vacuumed and examined.

Occasionally in my eagerness/laziness after acquiring a new LP, I give in to the urge to play a record without cleaning it first. In my observations, I have never once found any evidence of ‘welding’ after cleaning an LP which has been played briefly before cleaning.

That being said, it’s always best to vacuum LPs before playing. It’s quick and easy to do, vastly improves playback and its the most effective way to save wear and tear on your stylus.

The one thing I will mention is that I occasionally note fairly evenly distributed white flecks under the white LED on certain records that, judging by the condition of the spindle hole, have seen heavy rotation (US Columbia LPs, for example). This seems to usually correspond to increased surface noise even with LPs that have no scuffs and scratches. These white flecks remain regardless of any cleaning.

Are these pieces of debris ‘welded’ to the surface of the LP after repeated play or symptoms of a rough and uneven vinyl surface in the grooves? I have no way of knowing. It has occurred to me to attempt the notorious wood-glue cleaning method often observed in YouTube videos in order to determine whether or not these flecks are debris or damage, but I haven’t yet mustered the courage to try it out.

The bottom line is this: while playing a dirty LP once or twice probably will have little to no effect, repeatedly playing dirty and dusty records is definitely very bad for your equipment regardless of whether it’s bad for your LPs. If you plan on investing any amount of money and time in your records and your turntable, a record cleaning machine is a necessity rather than a luxury.

LikeLike

I send the link to this post to my neighbour; after all it’s his VPI cleaner I always use. He simply uses the Knosti record cleaning fluid and so far I have nothing to complaint. In all modesty I can say that my vinyls absolutely look the business, but still my neighbour might like your approach of ‘record cleaning home brew’ 😉

LikeLike

This is my Process:

1. Homemade Enzyme cleaner (1 month to make) with a drop of triton x-100. Scrub hard with nail brush and let sit for an hour to let the enzymes go to town until dry. rewet and vacuum. Sorry those pig hair brushes just doesn’t do for me. Good old fashion Elbow grease..

2. Mixture of Distilled water, 99.9 alcohol, Soap and triton x-100

3 Distilled water with a triton x-100

Discovered the importance of surface tension two years ago when my son had a project to do at home.

LikeLike

Interesting approach – “enhanced cleaning” technique, sort of “waterboarding” for vinyl, give up the dirt and we will go easy on you. But those enzymes – is that fermenting yoghurt? Any particular flavour?

LikeLike

Wonderful post, Andy. Very illuminating and, frankly, EXCEPTIONALLY useful — something you don’t get to receive from many other vinyl blogs out there. The idea that one should pay GBP 20 (roughly $40.00) for a liter (quart) of “professional” record-cleaning reeks of road robbery – particularly when one can create a perfectly viable substitute for a tiny fraction of the the cost.

I have been using for decades a very similar formula: 30% ethyl alcohol, 70% distilled water, with only a few (3-4) drops of clean disinfectant soap (the cleaner and the more fragrance-free, the better). It proved to be remarkably useful. The only drawback to my formula is that I tend to err on the side of caution, so it may not be strong enough to dissolve and dislodge a caked piece of 60-year old meatball linguine con marinara embedded in the grooves, but on regular, vanilla-variety dust, grime and grease, it really does wonders.

Use of vinegar, lime, windex or – heavens forbid – industrial or household solvents (such as goof-off, lighter fluid, car gasoline, nail polish, ammonium, or similar) is STRICTLY, CATEGORICALLY, UNEQUIVOCALLY, PERMANENTLY FORBIDDEN, PERIOD. NO IFS, ANDS OR BUTS. Solvents can irreparably damage, even destroy, your vinyl, and anything that is lime- or acid-based may chemically react with the vinyl and significantly alter its chemical and acoustic properties.

Why ethyl alcohol? It has a better dissolving properties than isopropyl, although – on this side of the pond,at least – it is not as common as isopropyl alcohol and may be somewhat difficult to find (generally, most pharmacies have them, and purity grade is never an issue). And it disinfects better – something you really, truly, desperately need when your vinyl object of desire had been sitting in some godforsaken dump of a basement, collecting (pardon my phrase) vermin fecal matter and other ungodly, toxic or pathogenic discharge or infectious agents for decades

I have a habit of wiping off the record with pure distilled water AFTER the cleaning and ONLY THEN let it dry. Either that, or – with particularly badly soaked records – repeat the procedure twice, and only then wipe it off with a lint-free cloth soaked in distilled water.. This, in my humble view, helps remove any residual film from the surface.

I have heard reports from the collectors that alcohol tends to “dry” the sound of the vinyl. I am not sure what this means. If this implies that alcohol compresses the frequency response or dynamic range, I can confirm firsthand that nothing could be further from the truth. This is a figment of collective imagination, pure and simple. In any event, 30% solution is not strong enough to do any such thing.

Alcohol is a chemically (generally) neutral substance (barely higher acidic Ph value than that of water) and it will not, under normal environmental conditions, chemically bond with anything (obviously, if you bring a burning matchstick to it, it will) . However, under certain lab conditions or abnormal environmental circumstances, it does have a tendency to bond with the hydrogen molecules. Because the vinyl molecules are organized in firm crystalline matrix, alcohol cannot and will not “extract” hydrogen from the vinyl or otherwise rearrange vinyl matrix, but prolonged (15 minutes or longer) exposure of the vinyl to highly concentrated (70% of more) ethyl alcohol MAY increase the risk of crystalline matrix erosion. I have not had a single case like this in my 40 years of practice, but – again – to reiterate the obvious: alcohol (or any other cleaning solution) should ONLY be kept on the surface of the vinyl for as long as absolutely necessary and to get the job done and not one nanosecond longer. If the solution can’t clean the vinyl in 2 minutes (or less), you are flogging a dead horse.

You may be onto something when you say that the use of surfactants may be a key to success here. Bear in mind, however, that common household substances (such as clear liquid soap) can create the same effect, which is essentially the role it plays in my formula. I have absolutely no experience with Ilfotol (as a matter of fact, this is the first time I hear of it). One minor word of caution: I have no idea what Ilfotol is, chemically speaking. Alcohols can react with a variety of substances, mostly acids, to create alkyls, esters or alike. Mixing alcohols with other substances runs the risk of chemically altering BOTH compounds, which means that your vinyl may receive chemical substance significantly different from either compound if the two tend to react (not likely, but possible). I tried learning more about Ilfotol, online but could not locate any information about its chemical composition, which probably means that it is a proprietary mix of some sort. The reports of its strong smell, however, seem to signify that it is a benzene or benzene- or toluene- based compound). If correct, this would call for extreme caution in applying it to the vinyl. The caution should be QUADRUPLED if Ilfotol turns out not to be water-soluble.

Finally – and this is of paramount importance – NO LIQUID WHATSOEVER should so much as touch the labels — EVER! PERIOD! Not only are cheaply-glued labels (Debut, Storyville, Autumn, etc) susceptible to peeling-off, some of the labels, particularly those with bright or vivid colors (cinnamon red seems to be the biggest problem) dissolve and smear easily, creating a real nasty mess of a problem (see: Law of Unintended Consequences 0.0.1.). Collectors of Blue Note pressings – particularly those pressed before 1965 – which is 95% of all desirable titles – probably already know how dreadfully sensitive blue color on them is. You touch it with a wet finger, and it smears. Cleaner on Blue Note labels? Not even in a dream!

LikeLike

Excellent post Andrew–I’ll be following in your footsteps on this. When I got my VPI I dug around on the forums and got some “homebrew” ideas very similar to what Bob describes above. I ended up using an 80/20 mix with the purest iso alc I could find at the store. It has worked well and seems to do a nice job cleaning up LPs, but I’ve considered getting something from a retailer to clean my nicest and most valuable titles. Look like I can just buy stuff and have a “high end homebrew”–thanks again.

LikeLike

I’ve been using almost the same formula as you do, except I went for safer surfactants that are 100 % removeable (Laura Dearborn’s formula from her book ‘Good Sound’. You’ll find the famous formula where Triton X-110 or 114 is advised. Also a combination of Tergitol S-3 and Tergitol S-9 is a favorite. The only hard part was to be able to buy them as a non-chemist. Until I came across Talas

http://apps.webcreate.com/ecom/catalog/product_specific.cfm?ClientID=15&ProductID=17342

http://apps.webcreate.com/ecom/catalog/product_specific.cfm?ClientID=15&ProductID=17376

2 drops of each Tergitol on 500 ml of fluid is more than sufficient or 4 Tergitol drops.

LikeLike

I use a combination of distilled water and Tergitol S-3 and Tergitol S-9 (thanks, Talas!) and it is cheap, easy and very, very effective. In fact, when I first used it in a 5%-5% solution it was a little too effective: it gradually dissolved the glue which held the felt around the nozzle of my record vacuum until it was completely gone. At this point I use only a %0.625 concentration of each which presents no problems.

It’s one of the few fluids I’ve used that gets rid of fingerprints (Tergitol 15-S-3 is oil-soluble).

For those interested in a particularly gruesome dissection of the topic at hand (including the whole isopropyl alcohol/plasticizer thing) by someone with a background in chemistry, I highly recommend this post on Audiogon:

http://forum.audiogon.com/cgi-bin/fr.pl?eanlg&1124989009&openusid&zzJustin_time&4&5

LikeLike

Thanks as always Felix, in the knowledge-sub it’s dive dive dive.

“As long as the concentration of alcohol is low and the applied liquid quickly removed from the Vinyl surface with a powerful vacuum, an alcohol/water cleaner is perfectly safe”. I got that one.

Everything you do has consequences, which are by definition your fault, but what you inherit from others is a crappy dirty noisy LP which needs a remedy. I do not adhere to the precautionary principle, myself: to do nothing in case you are blamed for something. I experience from listening that “prudent” cleaning does enormous good, and if a few molecules have gone AWOL, well the Chemistry Professor may be right but I can’t hear it.

Seems to be no actual measure of vinyl “brittleness” or “leeching of plastylizer” , that would pass a listening test, so it could be a hypothetical risk, possibly like effects outside human hearing frequency. Not to say the science is wrong, but it gets you only so far. After that, its down to us risk-takers.

LikeLike

I agree whole-heartedly. I’m certainly not advocating for using only alcohol-free RCF or trying to perpetuate the misperception that isopropyl alcohol is some kind of imminent threat to LPs.

For me, the takeaway from the Audiogon post is that while isopropyl alcohol (and, interestingly, most other RCF components) can in theory leach out plasticizer if they are left on the surface of the record for an extended period of time, the risk is very small and can be completely eliminated as long as the record is thoroughly rinsed).

My own impression is that the author, being of the scientific persuasion, was describing the problem in terms of theoretical absolutes rather than at a level of practical importance with regards to the issue plasticizer leaching.

LikeLike

Great write-up on your LJC record cleaner and being a retired chemical engineer with experience in photographic processing, I can only state: excellent job done!

Will surely copy your cleaner for my own vinyls!

LikeLike